Вибрационная шаровая мельница Tencan ZM-20L с частотным преобразователем, керамические / циркониевые / PTFE футеровки

Подробная информация о продукте:

| Место происхождения: | Хунань, Китай |

| Фирменное наименование: | TENCAN |

| Сертификация: | CE |

| Номер модели: | ZM-20 |

Оплата и доставка Условия:

| Количество мин заказа: | 1 КОМПЛЕКТ |

|---|---|

| Цена: | Подлежит обсуждению |

| Упаковывая детали: | Шперплатный корпус + Пенопласт |

| Время доставки: | 20-30 рабочих дней после получения полной оплаты. |

| Условия оплаты: | T/T, Western Union |

| Поставка способности: | 100 комплектов в месяц |

|

Подробная информация |

|||

| Наименование продукта: | Свежий вибрационный шаровой мельница | Model NO.: | ZM-20 |

|---|---|---|---|

| Напряжение: | 380В | Сила: | 1.5 кВт |

| Частота винирования: | 1440 rpm | Контроль скорости: | Контроль частоты |

| Общий объем: | 20 л | Максимальная вместимость: | 10 л |

| Выделить: | Вибрационная шаровая мельница с частотным преобразователем,Легкая вибрационная шаровая мельница 20 л,Вибрационная шаровая мельница с циркониевыми шарами |

||

Характер продукции

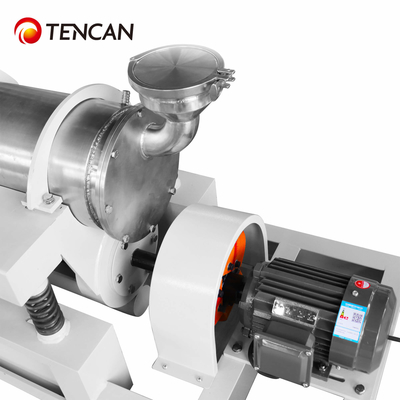

20-литровый легкий виброшаровой мельница с частотным преобразователем и керамическими, циркониевыми и PTFE футеровками

Обзор

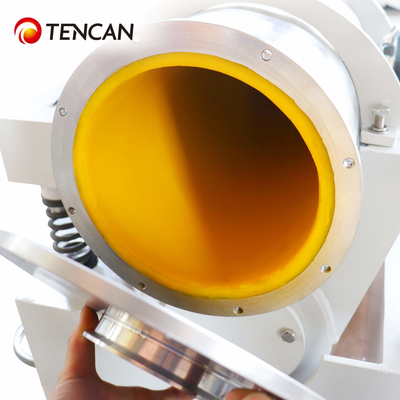

Легкий виброшаровой мельница, также называемая вибрационной мельницей, представляет собой инновационное поколение высокоэффективного оборудования для обработки порошков. Доступная в трех конфигурациях - с одним, двумя и тремя цилиндрами - это компактное решение для измельчения сочетает в себе исключительную производительность и простоту использования. Лабораторная виброшаровая мельница обеспечивает надежные возможности обработки, требует минимального обслуживания, демонстрирует отличную экологическую совместимость (отсутствие выбросов загрязнений) и поддерживает как сухие, так и мокрые процессы измельчения. Клиенты могут выбирать из нескольких вариантов футеровок цилиндров, включая: пищевую нержавеющую сталь 304/316L, высокочистую керамику из оксида алюминия (корунд), оксид циркония, стабилизированный иттрием, а также инженерные полимеры (нейлон, полиуретан, PTFE, PP, PE).

Принцип работы

Оптимизированная механическая система легкой виброшаровой мельницы включает в себя усиленную раму, прецизионное шасси, высокопроизводительный вибратор, узел измельчающего цилиндра, демпфирующие пружины и энергоэффективный двигатель. При активации двигатель передает мощность на вибрационный генератор, создавая контролируемые высокочастотные колебания (обычно 1000-3600 вибраций в минуту) с точно регулируемой амплитудой (0,5-5 мм). Это движение вызывает интенсивное многонаправленное движение измельчающей среды, способствуя:

Непрерывным высокоскоростным ударам

Эффективному истиранию поверхности

Однородному уменьшению размера частиц

Что приводит к превосходной эффективности измельчения и равномерной тонкости продукта.

Применение

Эта универсальная вибрационная мельница легкого типа служит для различных промышленных и исследовательских применений:

Производство электроники: диэлектрическая керамика, ферритовые сердечники, проводящие пасты

Передовые материалы: нанокомпозиты, квантовые точки, материалы для аккумуляторов

Химическая обработка: катализаторы, неорганические пигменты, полимерные добавки

Порошковая металлургия: вольфрамовые сплавы, карбидные порошки, металломатричные композиты

Фармацевтика: микронизация API, рецептуры с контролируемым высвобождением

Специальные продукты: магнитные материалы, резиновые смеси, радиочастотные компоненты

Особенности

1. Имеет большую емкость по сравнению с другими шаровыми мельницами.

2. Простая структура, путем регулировки амплитуды, частоты, среды. Различное соотношение дает различный размер частиц.

3. Виброшаровая мельница с рубашкой может регулировать температуру измельчения.

4. Виброшаровая мельница с ситом и устройствами для сбора обеспечивает непрерывное производство.

5. Простое и удобное управление, надежная работа, легкая очистка, высокая адаптируемость к условиям работы.

6. Отсутствие загрязнения окружающей среды, возможно сухое и мокрое шаровое измельчение.

7. Легкий вес, небольшой объем, высокая эффективность.

8. Специальный заказ может быть сделан в соответствии с требованиями.

Технические параметры легкой виброшаровой мельницы Tencan

| Технические параметры легкой виброшаровой мельницы | ||||||

| Модель № |

Общий Объем |

Максимальный объем загрузки | Электропитание | Доступный барабан | Размер подачи | Выход Гранулярность |

| ZM-10 | 10 л | 5 л | 380 В/1,5 кВт | Может быть облицован: Полиуретан Нейлон Керамика из оксида алюминия Цирконий PTFE |

≤10 мм | ≤1μm |

| ZM-15 | 15 л | 7,5 л | 380 В/1,5 кВт | ≤10 мм | ≤1μm | |

| ZM-20 | 20 л | 10 л | 380 В/1,5 кВт | ≤10 мм | ≤1μm | |

Доступные мельничные банки: мельничная банка из нержавеющей стали, мельничная банка из керамики из оксида алюминия, мельничная банка из циркония, мельничная банка из агата, мельничная банка из карбида вольфрама, мельничная банка из полиуретана, мельничная банка из нейлона, мельничная банка из PTFE и т. д.

![]()

| Рекомендации по подбору решений для мельничных банок и материалов | |

| Категории материалов | Рекомендуемые мельничные банки |

| Почва и другие материалы, в которых не допускается наличие каких-либо примесей | Мельничная банка из агата |

| Металлические и неметаллические материалы, в которых не допускается наличие каких-либо примесей | Мельничная банка из циркония |

| Материалы высокой твердости, такие как алмаз, карбид вольфрама | Мельничная банка из карбида вольфрама |

| Сильные добавки и щелочные материалы или другие материалы при высокой температуре | Мельничная банка из PTFE |

| Материалы железной руды с меньшей чувствительностью к примесям | Мельничная банка из нержавеющей стали 304 |

| Пигменты или другие материалы с последующей обработкой при высокой температуре | Мельничная банка из нейлона |

| Алюминиевые материалы, такие как керамическая глазурь | Мельничная банка из корунда |

| Электронные материалы, такие как литиевая батарея | Мельничная банка из полиуретана |

| Легко окисляемые материалы или некоторые специальные материалы, которые необходимо защищать в специальной атмосфере. |

Вакуумная мельничная банка |

| Ссылки о шлифовальных средах и материалах | ||

| Материалы Шлифовальная среда |

Твердость (Шкала Мооса) |

Особенности |

| Циркониевые шарики | ≥9.0 | Сверхстойкость к истиранию, без каких-либо примесей, коррозии и устойчивость к высоким температурам. |

| Шарики из нержавеющей стали | ≥6.0 | Износостойкость, общая коррозионная стойкость, устойчивость к высоким температурам. |

| Агатовые шарики | ≥7.0 | Сверхстойкость к истиранию, используется для медицины, пищевых продуктов и других материалов, которые не могут быть загрязнены металлом, коррозией и устойчивостью к высоким температурам. |

| Алюминиевые шарики | ≥8.5 | Износостойкость, коррозионная стойкость и устойчивость к высоким температурам. |

| Шарики из карбида вольфрама | ≥9.0 | Сверхстойкость к истиранию, без каких-либо примесей, коррозии и устойчивость к высоким температурам. |

| Соответствующие решения для мельничных банок и шариков | |||||

| Элементы | Агатовые шарики | Алюминиевые шарики | Шарики из нержавеющей стали | Циркониевые шарики | Шарики из карбида вольфрама |

| Агатовая мельничная банка | √ | ||||

| Корундовая мельничная банка | ▲ | √ | ▲ | ||

| Мельничная банка из нержавеющей стали | √ | ||||

| Циркониевая мельничная банка | ▲ | √ | |||

| Нейлоновая мельничная банка | ▲ | √ | |||

| PTFE мельничная банка | √ | ▲ | |||

| Полиуретановая мельничная банка | √ | ▲ | |||

| Мельничная банка из карбида вольфрама | ▲ | √ | |||

| √ означает: наиболее подходящий ▲ означает: подходит | |||||